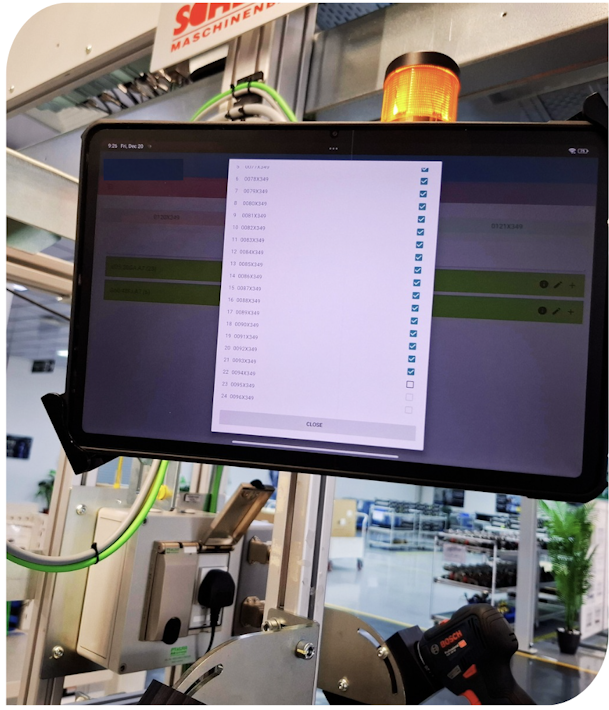

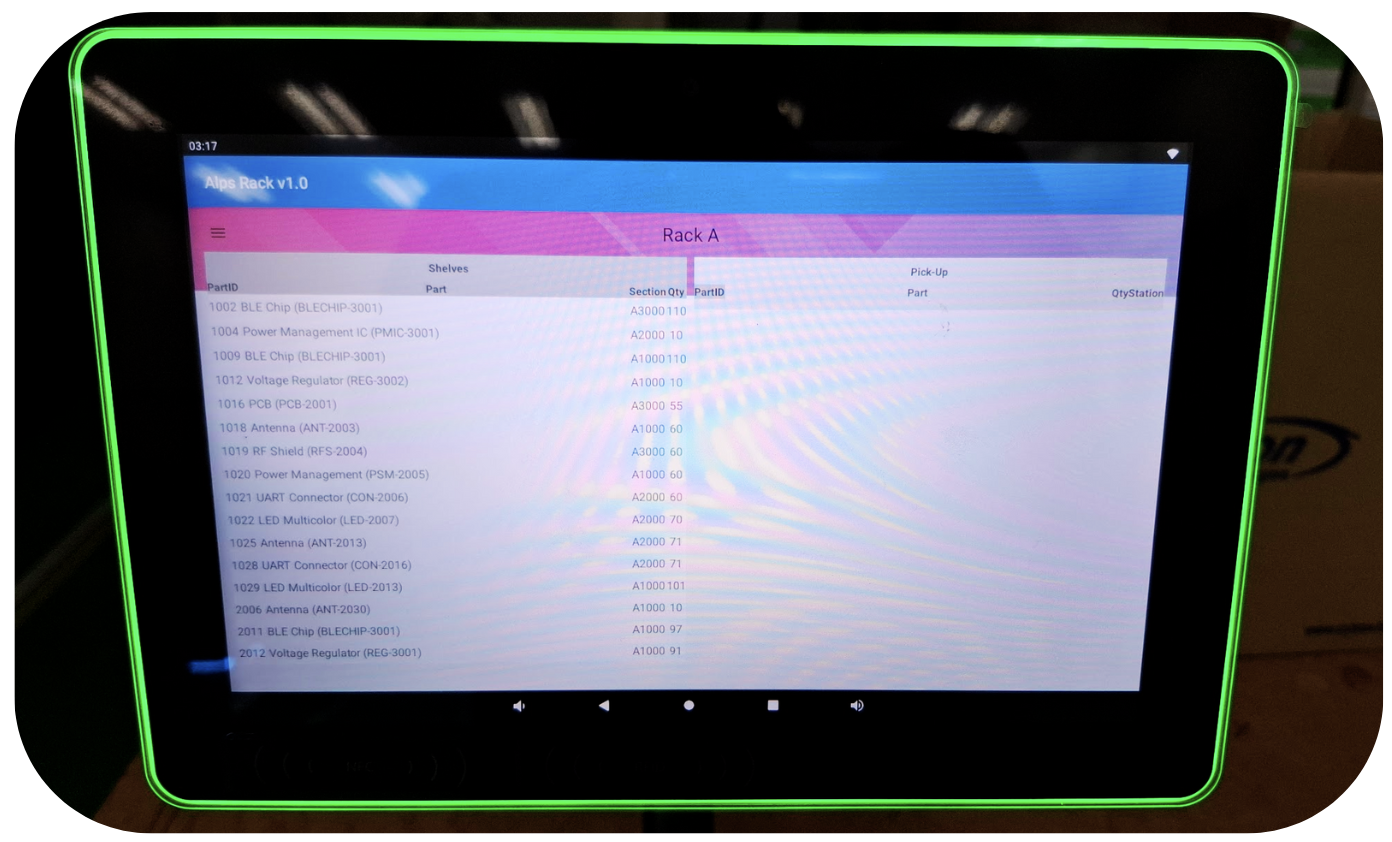

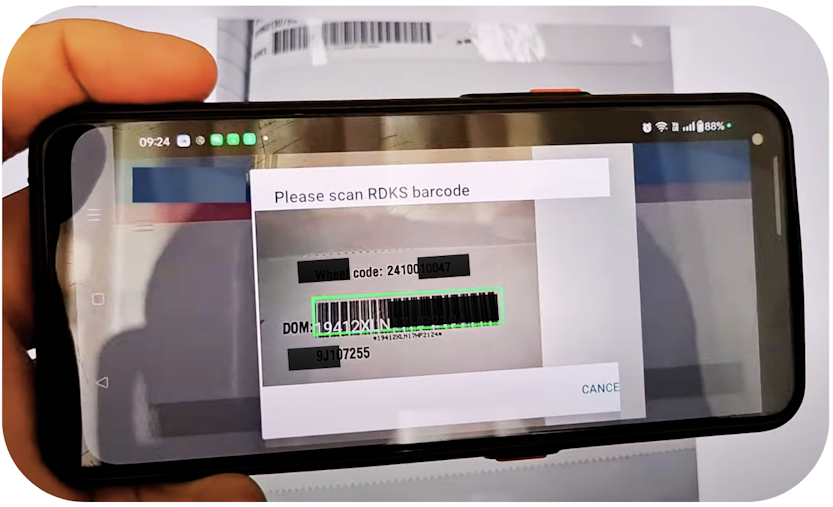

Elevating Industry with Smart Technology.

Pioneering a smarter tomorrow by integrating advanced mechatronics, data-driven insights, and cutting-edge technology—unlocking new frontiers in industrial innovation with unwavering passion and precision

Explore Our Solutions Contact us